Custom Blended

Resin Coated Sand

Resin Coated Sand

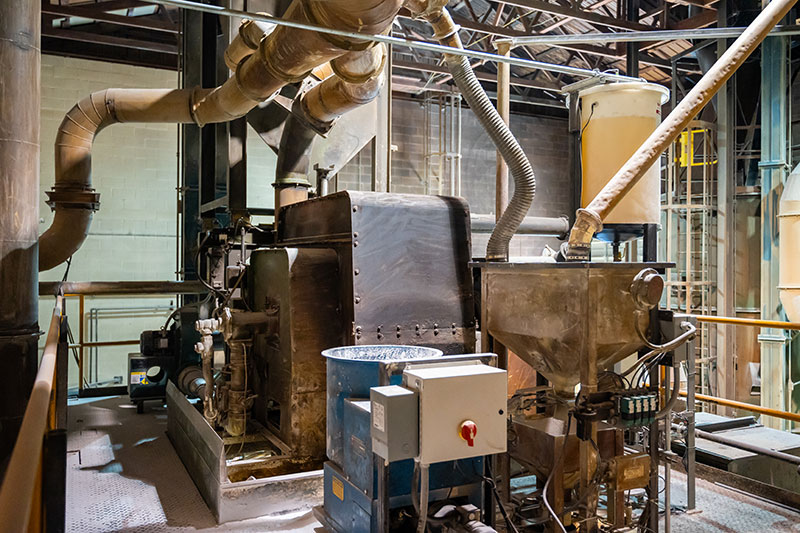

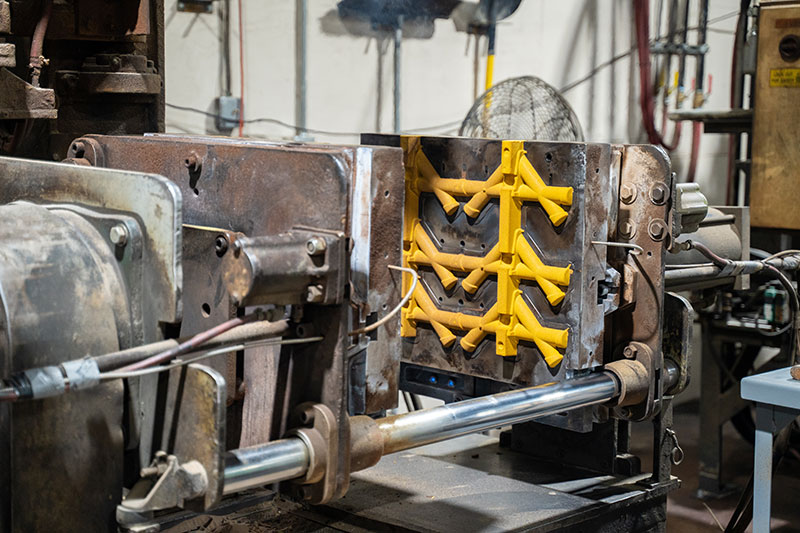

Being Core Makers gives us a unique perspective on manufacturing resin coated sand. We use over 60 tons of resin coated sand in our own core department every week. We want the sand to be strong, easy to work with, dust free, and consistent. We understand the significant impact that the right resin coated sand can have on the quality of your shell cores.

Kore Mart is committed to delivering exceptional results by providing custom resin coated sand blends tailored to your specific requirements. Here’s how our custom blending process sets us apart:

Trained Technicians

Our team of trained technicians possess extensive expertise in resin coated sand blending. They will carefully assess your specific requests and utilize their knowledge to prepare the perfect blend of sands, resins, and additives that align with your unique needs.

State-of-the-art Testing Lab

Tailored Solutions

Small Batches

Our Offerings

Kore Mart understands the diverse needs of foundries, and we offer an assortment of resins specifically tailored to meet your unique requirements. Our meticulous approach ensures that we carefully select high-quality sands and resins during the preparation process.

Here’s a closer look at our offerings:

Sand Selection

We recognize the importance of using the right type of sand for different applications. Our selection includes different grades of round and sub-angular sands, which are chosen based on their specific characteristics and compatibility with your casting processes. Additionally, we offer specialized sands such as zircon sand and ceramic sands, which provide exceptional performance in certain applications.Anti-Veining Additives

Minimizes veining defects in castings by improving mold surface characteristics and reducing the penetration of molten metal.Shakeout Sand

Facilitates easier and more efficient shakeout of cores, reducing casting cleaning time and improving productivity.Odor Masking

Manages and minimizes the generation of unpleasant odors during the core making process, creating a more comfortable working environment.Emission Reduction

Helps reduce harmful emissions during core making operations, ensuring compliance with environmental regulations and promoting sustainability.Improved Release

Dry powder lubricants are used to enhance the release properties of the sand, allowing for increased flowability and sand compaction.

Choosing Kore Mart means gaining access to our expertise in custom blending resin coated sand. By leveraging our trained technicians, advanced sand testing lab, and tailored solutions, you can expect superior results in your foundry operations. Our commitment to quality and attention to detail will make a noticeable difference in the performance of your products.

Contact us today to discuss your specific requirements and learn more about how our custom blending capabilities can enhance the quality of your foundry products. We look forward to partnering with you and providing the optimal resin coated sand solutions for your success.